Project Overview

Deliverables ✎

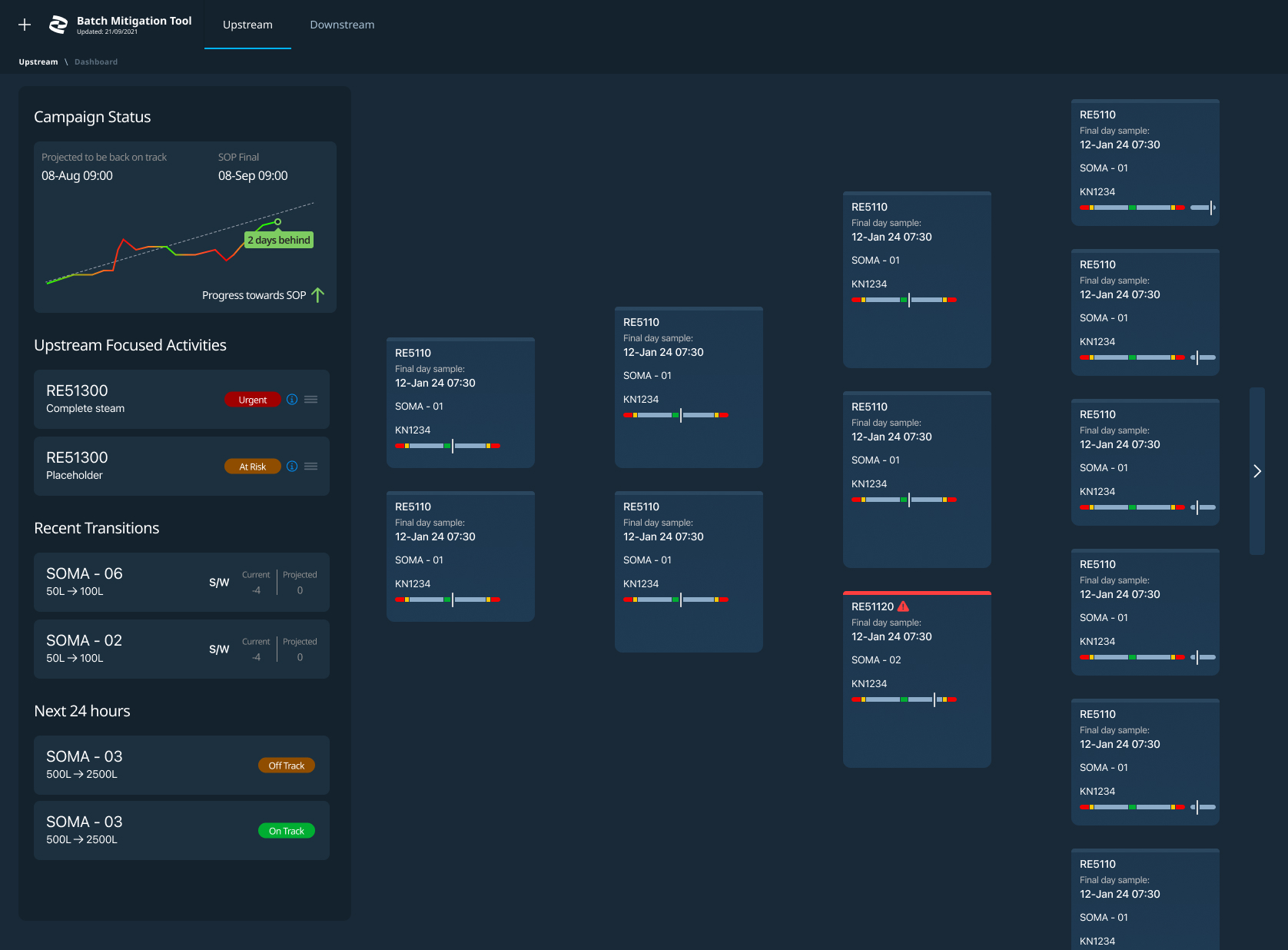

3-day Design Thinking Workshop → Traveled to Ireland to visit a drug substance facility and understand the manufacturing batch mitigation process with SMEs.

UI Design Mockups → High-fidelity Figma screens showing proof on concept. Went through multiple stakeholder reviews and iterations from low-fidelity sketches to high-fidelity mock-ups.

My Role

UX/UI Designer. I worked under the direction of the design lead. I co-presented designs to stakeholders and co-designed alongside a SME.

Design Methods

Design thinking workshop, particpatory design (co-design)

Tools

Figma, Mural

Duration

3 days (2024)

The Context

Drug substance facilities manufacture multiple batches simultaneously. Each batch takes a certain amount of time to finish and has defined timings that must be adhered to. However, if a batch runs off track/experiences a delay, then all batches before and after it must be mitigated, and their timings manipulated with their respective defined timing in order for manufacturing to continue smoothly.

The Problem

Currently this mitigation process is performed manually and reliant on operational leads with extensive knowledge of the processes who in turn decide what adjustments and interventions need to be made. This leaves plenty of room for human error and inefficiencies. Additionally, this is not the main job function of an opertaional lead so it takes away from their day-to-day duties.

The Objective

Understand the manufacturing batch mitigation process and design a solution to automate the process and empower operational leads in their day-to-day.

Image to the left is a screen deliverable for this project.

Lessons Learned

The value of being resourceful.

Due to the complexity of the topic, the design lead and I were stuck for the entire first day. We didn’t understand the manufacturing process and all the important details that needed to be prevalent in our designs. We looked for alternatives and tackled this challenge through creative problem solving. Instead of the traditional workshop flow, we decided to co-design 1:1 with the SME so that we could have more focused, simplified conversations about design.

When all feels a mess, focus on the outcomes.

By being outcome focused, we moved away from trying to understand the details to focusing on what we needed to deliver - designs. We used the co-design 1:1 session to help us achieve this.

Take a look at my other projects 𓀙

UnitedAirlinesProject type

Streamlining the candidate hiring experienceIBM Internship Project

Reimagining remote work connectionsSemester project with Dolby Labs

Empowering Purdue students with physical disabilitiesDigital Civics Project

Motivating first-generation college studentsSemester project with Innovatemap

Using AR to improve a shopping experienceSemester project with UE Group